|

Catalog •

Video •

Packages •

Library •

Process •

Stencil •

Printer •

Tray •

Align •

Planar •

Vacuum •

Interposer •

Columns •

Flip-Pack® |

| |

| Column Attachment Tools for Solder Columns and Micro-coil Springs |

About Tool-Kit:

TopLine manufactures a complete set of precision tools to attach Solder Columns and Micro-coil Springs to your specific CCGA column grid array package. Our tools hold cylindrical solder columns vertically at true 90° during the entire assembly process.

Use our tool-kit to columinize a fresh LGA or rework a damaged CCGA for full-use deployment. The tool-kit includes a benchtop graphite set and accessories such as a vacuum chuck, alignment template, insertion tool, extraction tool and solder paste printer for a professional job.

Simple column attachment process steps using new Flip-Pack®

CCGA Features:

Size: 8x8mm ~ 100x100mm

Pitch: 0.5mm ~ 1.27mm

Substrates: Ceramic, Organic (Plastic) or Silicon (Si)

Column Length: 0.63 ~ 3.8mm

Column Diameter: Ø0.20 ~ Ø0.56mm

|

C7 Series TOOL SET

10 Piece Tool Set REQUIRED ITEMS |

| Tool |

Series |

Model |

Description |

Image |

| GRAPHITE SET |

71xxxx

72xxxx |

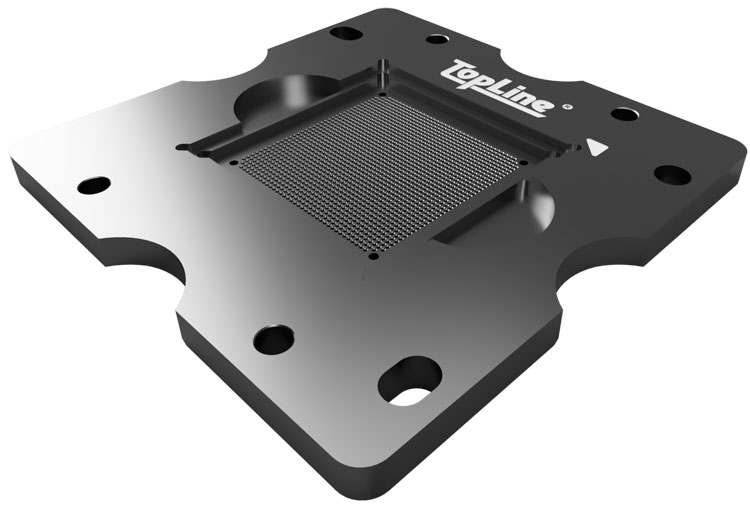

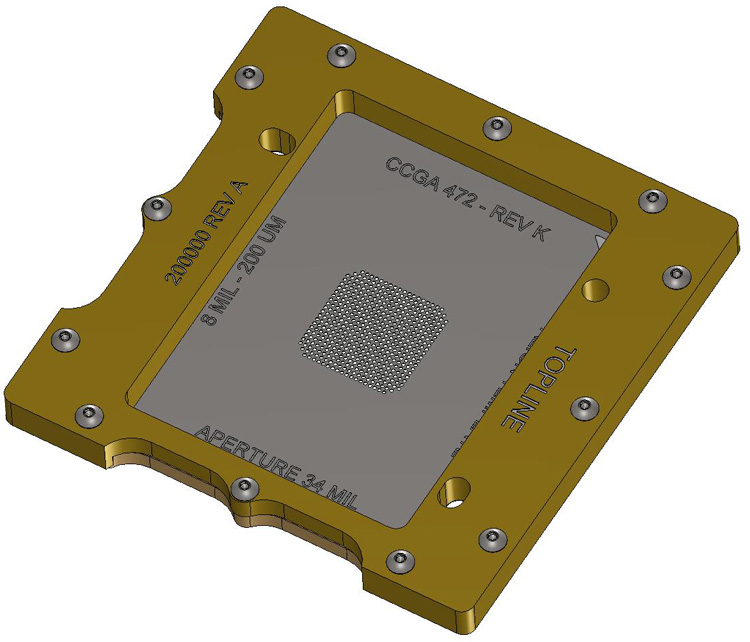

C7-TOP |

Graphite structure with array of holes to match CCGA pads. Holds columns upright. Bottom side has downset to clear solder paste fillets. Top side has receptacle to accept optional Flip-Pack® U.S. Patents D808350. |

|

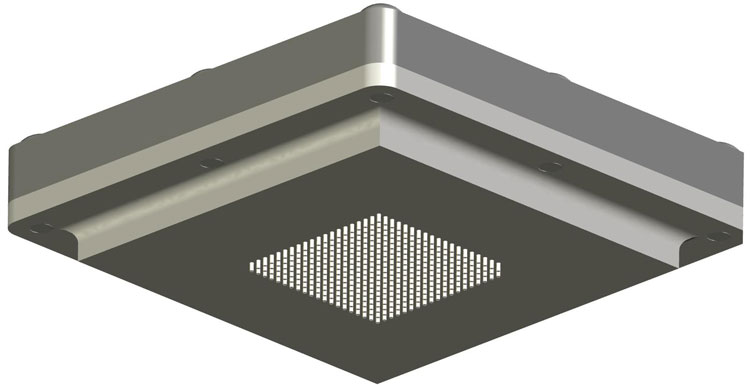

| 5xxxxx |

C7-STAGE |

Adjustable X/Y stage holds and aligns LGA/CCGA substrate pads. Channels permit optional thermocouples to measure temperature at substrate during reflow. Vacuum center hole prevents substrate from lifting. Patent Pending. |

|

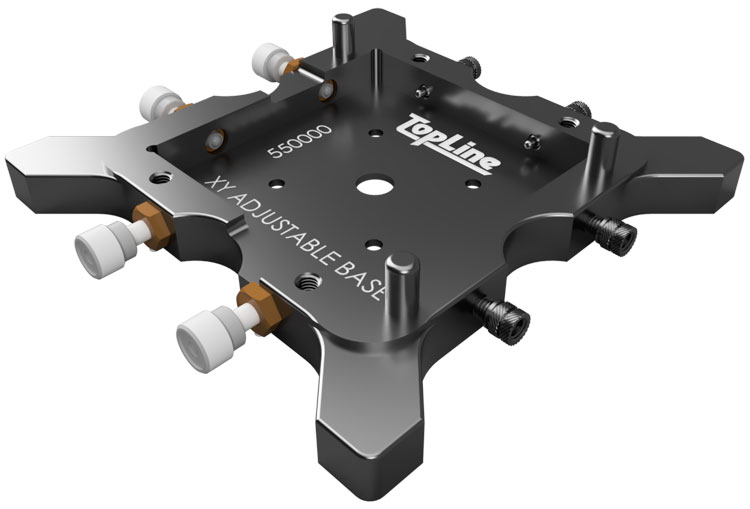

| 550000 |

C7-BASE |

Base has ultra-fine threaded adjustment to align the stage in X/Y directions. Includes 3 precision alignment pins. The C7-BASE sits on top of vacuum chuck to secure the substrate in the stage. Patent pending. |

|

| TAMPING TOOL |

41xxxx

42xxxx |

C7-TAMP |

Array of independant Titanium (Ti) pins gently pushes solder columns uniformly into solder paste on substrate. Includes special frame, top cover plate, titanium pins and high temperature silicon rubber gasket. Seats securely onto top graphite plate. |

|

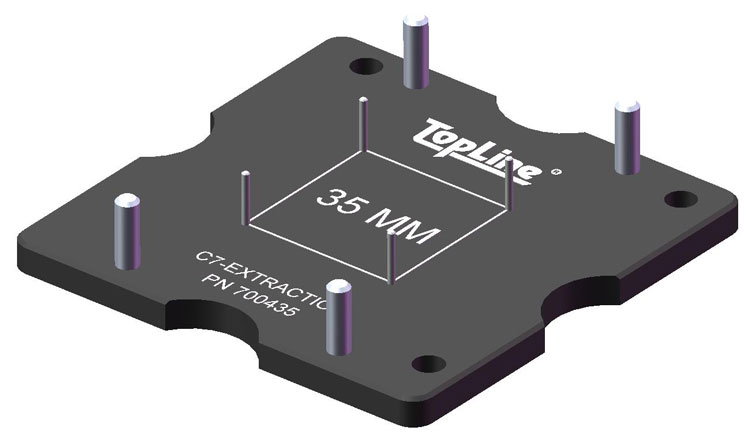

| EXTRACTION TOOL |

703xxx |

C7-EXTRACT |

Precision dowel pins safely lifts CCGA substrate by 4-corners from the Graphite top plate after reflow |

|

| ALIGNMENT |

200xxx |

C7-ALIGN |

Essential tool for centering and accurate X/Y Theta alignment of LGA in graphite. Includes precision alignment template with aperture allowing annular ring vision of LGA pads while seated in graphite |

|

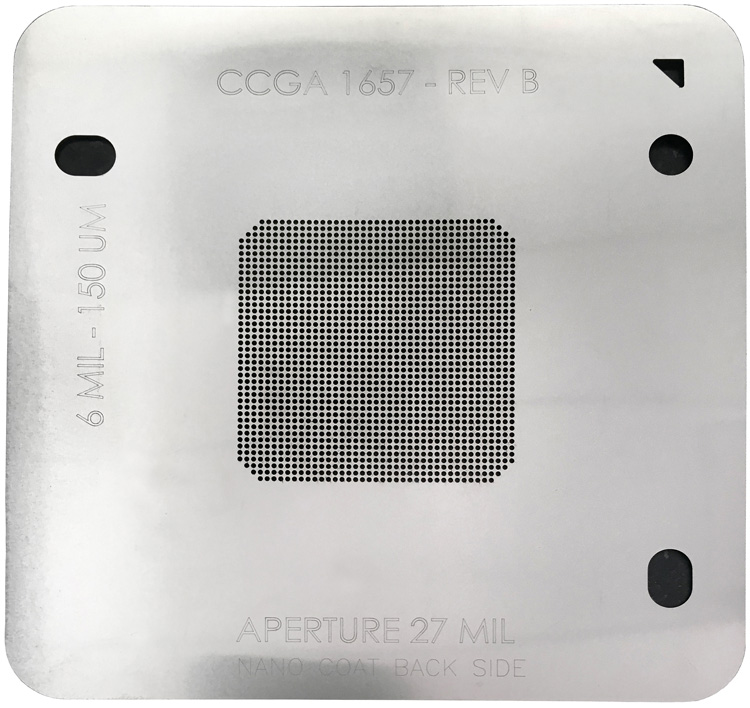

| PASTE STENCIL |

61xxxx

62xxxx |

C7-STENCIL |

Set of laser cut stainless steel stencils with a choice of apertures for optimizing solder paste volume. Micro-etched stencil surface with nano-coating assures clean solder paste deposits to LGA seated in Graphite Set. |

|

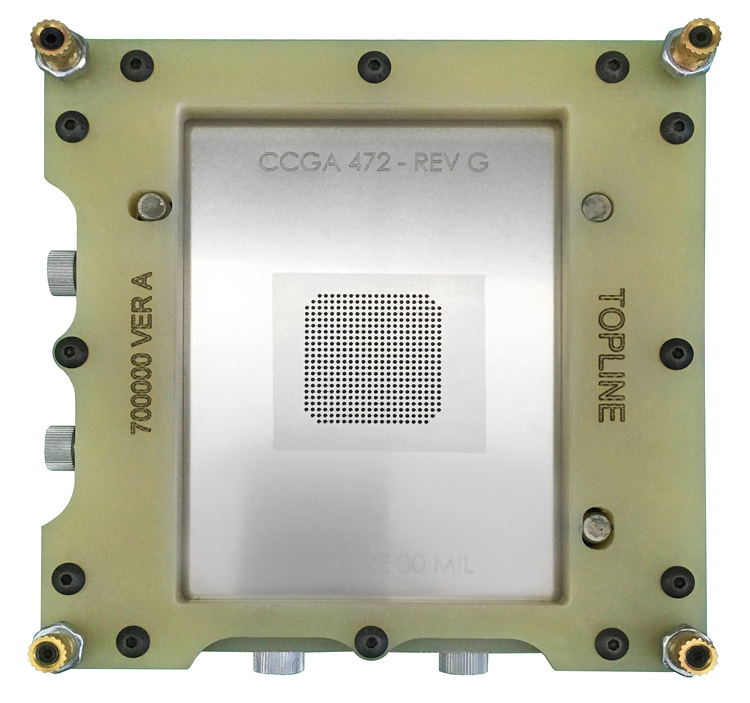

| STENCIL PRINTER |

700000 |

C7-PRINTER |

Simple to use manual stencil printer for applying solder paste while LGA sits in graphite. Adjustable spring back for clean solder paste deposits. Includes stainless steel stencils and metal doctor blade squeegee |

|

| PLANARIZING |

700xxx |

C7-PLANAR |

Securely holds and protects CCGA while planarizing Solder Columns using fine-grit silicon carbide lapping media and diamond polishing film of your selection. Includes precision machined brass plate and two step shims. Not required for Micro-coil springs. |

|

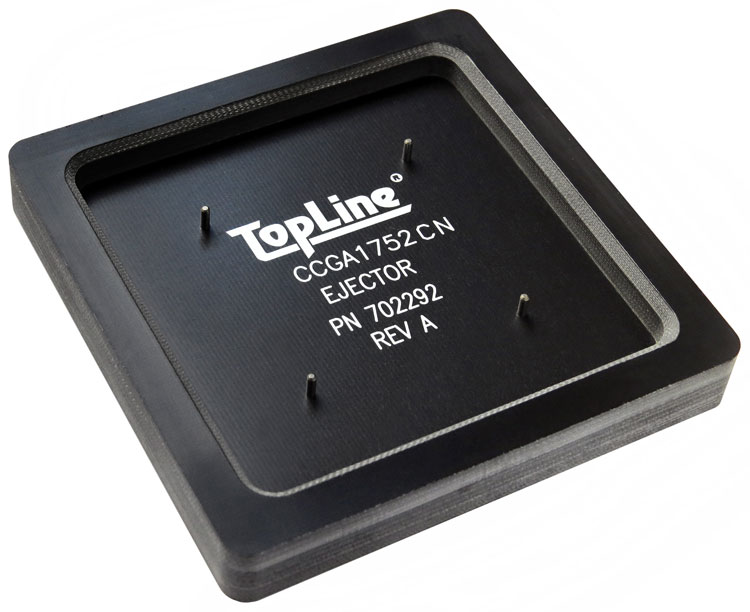

| 702xxx |

C7-EJECT |

Simple to use tool to extract CCGA from Planarizing tool. Gently lifts substrate at 4-corners with precision dowel pins. |

|

| |

|

| Note 1: Consult with TopLine for recommended tools for your application. |

| |

| |

| |