|

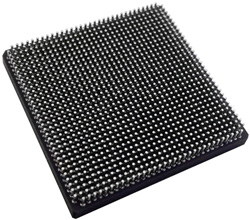

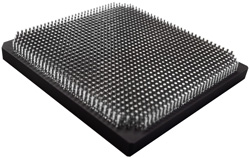

CCGA Ceramic Column Grid Array and LGA |

| |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Columns | Matrix | Pitch | Size (mm) | Pb80/Sn20 Internal Dummy Die |

Pb80/Sn20 Top Mounted Flip Chip Style Dummy Die |

Pb90/Sn10 Internal Dummy Die |

Pb90/Sn10 Top Mounted Flip Chip Style Dummy Die |

Outline Drawing |

| 255 | 16x16 | 1.27mm | 21mm | CCGA255T1.27-DC161D | CCGA255T1.27-DC161D | CCGA255T1.27A-DC161D | CCGA255T1.27A-DC161D | Under Development |

| 349 | 19x19 | 1.27mm | 25mm | - | - | CCGA349T1.27A-DC19xD | CCGA349T1.27A-DC19xD | Under Development |

| 360 | 19x19 | 1.27mm | 25mm | CCGA360T1.27-DC198D | CCGA360T1.27-DC198D | CCGA360T1.27A-DC198D | CCGA360T1.27A-DC198D | Under Development |

| 472 | 22x22 | 1.27mm | 31mm | CCGA472T1.27-DC226D | CCGA472T1.27-DC226D | CCGA472T1.27A-DC226D | CCGA472T1.27A-DC226D | Under Development |

| 517 | 23x23 | 1.27mm | 31mm |

|

|

|

|

PDF Under Development |

| 717 | 27x27 | 1.27mm | 35mm |

|

|

|

|

PDF Under Development |

| 1089 | 33x33 | 1.27mm | 42.5mm | CCGA1089T1.27-DC339D | CCGA1089T1.27-DC339D | CCGA1089T1.27A-DC339D | CCGA1089T1.27A-DC339D | Under Development |

| 1144 | 34x34 | 1.0mm | 35mm |

|

|

|

|

PDF Under Development |

| 1247 | 31x41 | 1.0mm | 32.5x42.5mm | CCGA1247T1.0-DC3141D | CCGA1247T1.0-DC3141D | CCGA1247T1.0A-DC3141D | CCGA1247T1.0A-DC3141D | Under Development |

| 1588 | 40x40 | 1.27mm | 52.5mm | CCGA1588T1.27-DC407D | CCGA1588T1.27-DC407D | CCGA1588T1.27A-DC407D | CCGA1588T1.27A-DC407D | Under Development |

| 1657 | 41x41 | 1.0mm | 42.5mm |

|

|

|

|

PDF Under Development |

| 1752 | 42x42 | 1.0mm | 45mm | CCGA1752T1.0-DC427D | CCGA1752T1.0-DC427D | CCGA1752T1.0A-DC427D | CCGA1752T1.0A-DC427D | Under Development |

| 2577 | 51x51 | 1.0mm | 52.5mm |

|

|

|

|

PDF Under Development |

| ||||||||

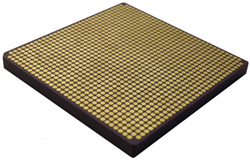

| CLGA - Ceramic Land Grid Array with Daisy Chain • Application Practice Attaching Columns | ||||||||

|

||||||||

| Click to Enlarge | ||||||||

| Columns | Matrix | Pitch | Size (mm) | Part Number | Die Style | Pad Material |

Pad Diameter |

|

| 624 | 25x25 | 1.27mm | 32.5mm | CCGA624T1.27-DC254D | Internal Dummy Die |

Ni/Au | Ø0.86mm | |

| 1152 | 34x34 | 1.0mm | 35mm | CCGA1152T1.0-DC346D | Internal Dummy Die |

Ni/Au | Ø0.80mm | |

| 1272 | 36x36 | 1.0mm | 37.5mm | CLGA1272T1.0-DC367D | Internal Dummy Die |

Ni/Au | Ø0.80mm | |

| ||||||||

| NASA GSFC-STD-6001: | ||||||||

| IBM Solder Column: Pb90Sn10 2.21mm L x 0.51mm diameter and 1.62mm L x 0.89mm diameter. | ||||||||

| Copper Wrapped Solder Column: Pb80Sn20, Sn-plated Cu Wrap, Sn63Pb37 Finish. 2.21mm L x 0.51mm diameter | ||||||||

| Component Inspection: | ||||||||

| Colpanarity: Less than +/-0.15mm (0.0059-inch) | ||||||||

| Single Column Tilt: An individual column shall not be bent more than 5° relative to other columns | ||||||||

| Multiple Column Tilt: Tilt is acceptable if all columns are tilted uniformally up to maximum 10° | ||||||||

| Visual Inspection: Use 10X magnification | ||||||||

| PWB Board Requirements: | ||||||||

| PWB Board Material: Polyimide recommended due to lower CTE compared with epoxy-class boards. | ||||||||

| PWB Allowed Finish: Tin-lead solder or Electroless-Nickel, Immersion Gold (ENIG). Maximum 0.254µm (10 micro-inch) gold. | ||||||||

| PWB Prohibited Finish: Pure tin or other lead free surface plating is not allowed. | ||||||||

| PWB Pad Diameter: Non-Solder Masked Defined pads (NSMD) minimum 120% of solder column diameter | ||||||||

| PWB Component Courtyard: 0.3-inch (7.62mm) minimum clearance to allow sufficient clearance for rework. | ||||||||

| Assembly Requirements: | ||||||||

| Underfill: Not allowed under the CCGA component. | ||||||||

| Solder Paste Stencil: Laser cut stencils are recommend, instead of chem-etched stencils. | ||||||||

| Rework Requirements: | ||||||||

| Prohibited Reuse of Columns: Columns shall not be reused even if they remain attached to the CCGA part after removal from the board. | ||||||||

| Process Validation Testing: | ||||||||

| Electrical Continuity: Use daisy chained connections at -55°C , +100°C and +25°C to identify a failed attachment. | ||||||||

| For PC • MAC Version

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||