|

Catalog •

What is? •

FEA •

DCR •

CCGA Packages •

More Columns •

Columns Quickview •

Library •

Materials •

Tray •

Attachment Tools •

Attach Service

|

| |

|

MIL-STD-883L 3.3.6 •

Pull Stength: MIL-STD-883K TM2038 •

Reflow Temperature •

Cryo Questionnaire

•

Column Questionnaire |

|

| |

| Some applications, including Quantum Computers, perform better at cryogenic temperatures, below what is known as the superconductivity point. This is because electrical resistance drops to zero when certain materials become superconductive, allowing current to flow without energy loss. Our series of cryogenic solder columns are made of specific materials that perform reliably at cryogenic temperatures for deep space and Lunar landings. Cryogenic solder columns reduce stress and strain caused by CTE mismatch when connecting large chip modules to PC Boards. In addition, materials can withstand fracturing caused by ductile to brittle transistion temperatures (DBTT) at extremely low temperatures. Next Generation solder columns. TopLine offers a wide range solder columns to meet your cryogenic needs. The tables below are just a small example of the column sizes we offer. Contact TopLine to discuss your specific needs. |

|

|

| |

| With Lead (Pb) and Lead-Free Columns (RoHS) |

| Braided columns are available with Lead for Aerospace & Defense applications or Lead Free for RoHS AI Datacenters. Columns replace solder balls on ceramic substrates and Organic chip packages. |

| |

Why Columns? |

| Braided Solder Columns are non-collapsible, robust and compliant structures. Use for reducing stress caused by CTE mismatch. Columns are more reliable that solder balls when connecting large size chip packages to PC Boards operating in cryogenic environments. CTE mismatch (Coefficient of Thermal Expansion) puts stress on the interconnections over wide temperature cycles. The CTE of a ceramic alumina Al2O3 IC package is about 6.7ppm/°C. The CTE of organic copper clad boards is more than 17.5ppm/°C. Therefore, the amount of CTE mismatch between ceramic materials and organic boards is roughly 10ppm/°C. The corners of a large 50x50mm ceramic package might twist as much as ±70µm (±2.7mils) over temperature swings of 100°C. Eventually, the connections between the chip package and board will break over time. Solder columns are compliant and absorb CTE mismatch, thereby lengthening the life of the system. |

| |

More Details |

A wide selection of material sets are available. Tin-Lead for Mil/Aerospace: Pb80/Sn20 and Pb90/Sn10. Columns for Quantum Computers are constructed of Indium-Niobium Alloys. Animated Finite Element Analysis (FEA) Strain on Copper Wrapped Column under CTE mismatch.Road map solder columns for Quantum Computers. |

| |

| |

| Braided Solder Column Part Number Table |

|

Column

Ø Diameter

±0.05mm |

Column

Length

±0.05mm |

Core

Material |

Solder

Core

Ø Diameter |

Braid (W)

Ø Diameter |

Copper

Nbr

Strands |

Part Number |

Drawing |

Operating

Temperature |

Ø 0.25mm

(Ø 0.010") |

1.27mm

(0.050") |

Lead Free |

Ø 0.15mm

(Ø 0.006") |

0.025mm

(1.0 mil) |

16X |

BC10H10x50A |

951050 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.15mm

(Ø 0.006") |

0.025mm

(1.0 mil) |

16X |

BC8020B10x50A |

751050 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.15mm

(Ø 0.006") |

0.025mm

(1.0 mil) |

16X |

BC9010B10x50A |

711050 |

-180°C +150°C |

| HMP Pb93.5 |

Ø 0.15mm

(Ø 0.006") |

0.025mm

(1.0 mil) |

16X |

BC935M10x50A |

761050 |

-180°C +204°C |

|

Ø 0.30mm

(Ø 0.012") |

1.60mm

(0.063") |

Lead Free |

Ø 0.20mm

(Ø 0.008") |

0.025mm

(1.0 mil) |

16X |

BC10H12x63A |

951263 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.20mm

(Ø 0.008") |

0.025mm

(1.0 mil) |

16X |

BC8020B12x63A |

751263 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.20mm

(Ø 0.008") |

0.025mm

(1.0 mil) |

16X |

BC9010B12x63A |

711263 |

-180°C +150°C |

| HMP Pb93.5 |

Ø 0.20mm

(Ø 0.008") |

0.025mm

(1.0 mil) |

16X |

BC935M12x63A |

761263 |

-180°C +204°C |

|

Ø 0.35mm

(Ø 0.014") |

1.90mm

(0.075") |

Lead Free |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC10H14x75A |

951475 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC8020B14x75A |

751475 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC9010B14x75A |

711475 |

-180°C +150°C |

| In90/Ag10 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC90N14x75A |

111475 |

-273°C +120°C |

| In97/Ag3 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC97T14x75A |

131487 |

-273°C +120°C |

| In100 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC100T14x75A |

101475 |

-273°C +120°C |

| In70/Pb30 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC70N14x75A |

701475 |

-273°C +150°C |

| HMP Pb93.5 |

Ø 0.25mm

(Ø 0.010") |

0.025mm

(1.0 mil) |

16X |

BC935M14x75A |

761475 |

-180°C +204°C |

|

Ø 0.40mm

(Ø 0.016") |

2.21mm

(0.087") |

Lead Free |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC10H16x87B |

951687 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC8020B16x87B |

751687 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC9010B16x87B |

711687 |

-180°C +150°C |

| In90/Ag10 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC90N16x87B |

111687 |

-273°C +120°C |

| In97/Ag3 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC97T16x87B |

131687 |

-273°C +120°C |

| In100 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC100T16x87B |

101687 |

-273°C +120°C |

| In70/Pb30 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC70N16x87B |

701687 |

-273°C +150°C |

| HMP Pb93.5 |

Ø 0.25mm

(Ø 0.010") |

0.038mm

(1.5 mil) |

16X |

BC935M16x87B |

761675 |

-180°C +204°C |

|

Ø 0.45mm

(Ø 0.018") |

2.21mm

(0.087") |

Lead Free |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC10H18x87B |

951887 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC8020B18x87B |

751887 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC9010B18x87B |

711887 |

-180°C +150°C |

| In90/Ag10 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC90N18x87B |

111887 |

-273°C +120°C |

| In97/Ag3 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC97T18x87B |

131887 |

-273°C +120°C |

| In100 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC100T18x87B |

101887 |

-273°C +120°C |

| In70/Pb30 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC70N18x87B |

702087 |

-273°C +150°C |

| HMP Pb93.5 |

Ø 0.30mm

(Ø 0.012") |

0.038mm

(1.5 mil) |

16X |

BC935M18x87B |

761887 |

-180°C +204°C |

|

Ø 0.50mm

(Ø 0.020") |

2.21mm

(0.087") |

Lead Free |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC10H20x87B |

952087 |

-55°C +125°C |

| Pb80/Sn20 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC8020B20x87B |

752087 |

-140°C +150°C |

| Pb90/Sn10 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC9010B20x87B |

712087 |

-180°C +150°C |

| In90/Ag10 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC90N20x87B |

112087 |

-273°C +120°C |

| In97/Ag3 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC97T20x87B |

132087 |

-273°C +120°C |

| In100 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC100T20x87B |

102087 |

-273°C +120°C |

| In70/Pb30 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC70N20x87B |

702087 |

-273°C +150°C |

| HMP Pb93.5 |

Ø 0.35mm

(Ø 0.014") |

0.038mm

(1.5 mil) |

16X |

BC935M20x87B |

762087 |

-180°C +204°C |

|

| Note 1: Contact TopLine for other ØDiameter and Length available. |

| Note 2: Applications: RoHS AI Datacenters , Aerospace & Defense , Cryogenic , Quantum Superconducting , Downhole Elevated Temperature |

| |

| |

| Outline Drawings |

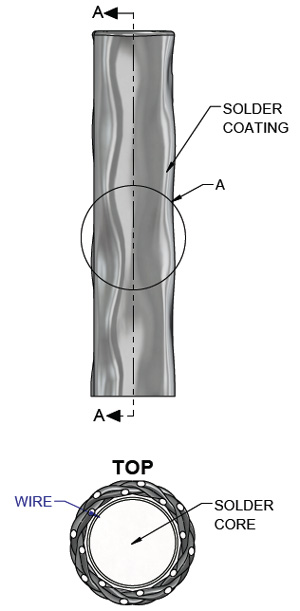

| Fig. 1 |

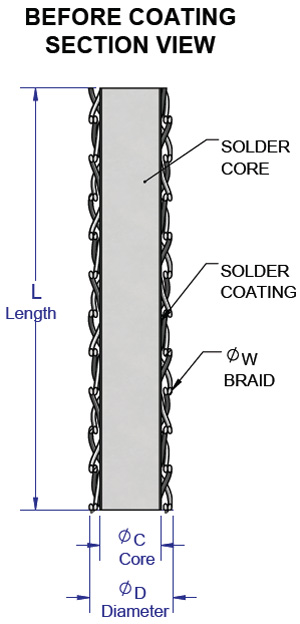

Fig. 2 |

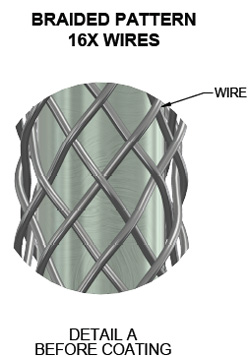

Fig. 3 |

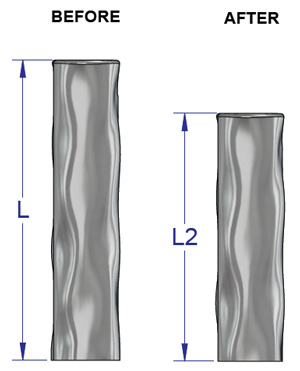

Fig. 4 |

Fig. 5 |

|

|

|

|

|

Braided Column

After Coating |

Section View

Before Coating |

Detail Solder Column

Before Coating |

Column Length

Before and After

Trimming (Planarization) |

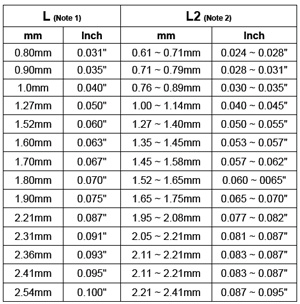

Column Length

L = Column Length as Delivered

L2 = After Trimming (Planarization) |

| |

| |

|

|

Column Part Number System

|

| BC |

9010 |

B |

14 |

X |

75 |

A |

| Column Type |

Core Alloy |

Coating |

Ø Diameter

Mils |

Packaging |

Length

Mils |

Option |

BC = Braided Column

Other Columns

|

Tin-Lead SnPb:

8020 = Pb80/Sn20

9010 = Pb90/Sn10

935 = HMP Pb93.5/Sn5

Lead Free (RoHS):

5 = Sn95/Sb5

8 = Sn91.5/Sb8.5

10 = Sn90/Sb10

Indium Alloy:

100 = Indium (In100)

97 = Indium/Silver (In97/Ag3)

90 = Indium/Silver (In90/Ag10)

70 = Indium/Lead (In70/Pb30)

Beryllium Copper Alloy:

172 = BeCu (C172N)

Patents Granted:

U.S. Patent 10,477,698

CN Patent 111,822,899

Indium-Niobium Pat. Pending

|

Tin-Lead

B = Sn63/Pb37 16*Cu

L = Sn63/Pb37 8*Cu

M = Pb80/Sn20 16*Cu

Lead-Free (RoHS)

H = SAC+In 16*Cu

J = SAC+In 8*Cu

Cryogenic

N = In97/Ag3

Q = In100

T = In52/Sn48

|

Ø Diameter

6 = 0.15mm

7 = 0.18mm

8 = 0.20mm

9 = 0.23mm

10 = 0.25mm

11 = 0.28mm

12 = 0.30mm

13 = 0.33mm

14 = 0.35mm

15 = 0.38mm

16 = 0.40mm

20 = 0.50mm

22 = 0.56mm

35 = 0.89mm

Other Diameter Available

|

Standard:

X = Jar

Special:

J = JEDEC Tray

T = 4" Tray

W = 2" Tray

E = Tape & Reel

|

Length

25 = 0.63mm

31 = 0.80mm

40 = 1.00mm

50 = 1.27mm

63 = 1.60mm

70 = 1.80mm

75 = 1.91mm

87 = 2.21mm

91 = 2.31mm

93 = 2.36mm

95 = 2.41mm

100 = 2.54mm

Other Length Available

|

Options: A to Z

Cyrogenic:

C172 Soft

A= 1.0mil

B= 1.5mil

C= 2.0mil

Superconducting:

Nb Niobium

M= 1.0mil

N= 1.5mil

R= 2.0mil

C172 Hard

D= 1.0mil

E= 1.5mil

F= 2.0mil

Cu-Pd (PCC)

G= 1.5mil

H= 2.0mil

Au Gold

J= 1.5mil

K= 2.0mil

|

|

| |

|

|

Column DP# Order Number

|

| 7 |

14 |

75 |

0 |

| Column Type |

Ø Diameter

Mils |

Length

Mils |

Package

Quantity |

Braided Column (BC) 16X:

4 = C172 Braid + Pb80/Sn20 Solder (B)

5 = C172 Braid + Lead Free Solder (H)

7 = C172 Braid + Pb90/Sn10 Solder (B)

Other Columns:

|

Code • Diameter

06 = Ø0.15mm

08 = Ø0.20mm

09 = Ø0.23mm

10 = Ø0.25mm

11 = Ø0.28mm

12 = Ø0.30mm

13 = Ø0.33mm

14 = Ø0.35mm

15 = Ø0.38mm

16 = Ø0.40mm

17 = Ø0.43mm

18 = Ø0.45mm

20 = Ø0.50mm

22 = Ø0.56mm

30 = Ø0.75mm

35 = Ø0.89mm

|

Code • Length

25 = 0.63mm

30 = 0.75mm

31 = 0.80mm

35 = 0.90mm

40 = 1.00mm

50 = 1.27mm

63 = 1.60mm

70 = 1.80mm

73 = 1.85mm

75 = 1.91mm

87 = 2.21mm

91 = 2.31mm

93 = 2.36mm

95 = 2.41mm

99 = 2.54mm

Other Lengths Available

|

Code • Qty

0 = Jar 100pcs

1 = Jar 1Kpcs

2 = Jar 5Kpcs

3 = Jar 10Kpcs

7 = Reel 2500pcs

8 = Tray

9 = Bulk

|

|

| |

|

|

Column Drawing Number

|

| 71 |

14 |

75 |

| Column Type and Plating |

Ø Diameter

Mils |

Length

Mils |

Braided Column (BC)

Lead Free (RoHS)

Code Core Alloy Braid Part#

95 Sn90/Sb10 16x (BC10H)

97 Sn95/Sb5 16x (BC5H)

98 Sn91.5/Sb8.5 16x (BC8H)

94 Sn90/Sb10 8x (BC10J)

96 Sn95/Sb5 8x (BC5J)

Leaded Core

Code Core Alloy Braid Part#

70 In70/Pb30 16x (BC70N)

71 Pb90/Sn10 16x (BC9010B)

75 Pb80/Sn20 16x (BC8020B)

76 HMP Pb93.5 16x (BC935M)

72 Pb90/Sn10 32x (BC9010D)

73 Pb90/Sn10 8x (BC9010L)

74 Pb80/Sn20 8x (BC8020L)

Indium Core

Code Core Alloy Braid Part#

10 In100 16x (BC100T)

11 In90/Ag10 16x (BC90N)

13 In97/Ag3 16x (BC97T)

70 In70/Pb30 16x (BC70N)

Beryllium Copper Core

Code Core Alloy Braid Part#

12 C172 16x Nb (BC172N)

Application Specific (ASIC)

89 = Customer Specific Assigned number

Other Columns:

|

Diameter

06 = Ø0.15mm

08 = Ø0.20mm

09 = Ø0.23mm

10 = Ø0.25mm

11 = Ø0.28mm

12 = Ø0.30mm

13 = Ø0.33mm

14 = Ø0.35mm

15 = Ø0.38mm

16 = Ø0.40mm

17 = Ø0.43mm

18 = Ø0.45mm

20 = Ø0.50mm

22 = Ø0.56mm

27 = Ø0.70mm

30 = Ø0.75mm

35 = Ø0.89mm

Other Ø Diameter Available

|

Length

20 = 0.50mm

25 = 0.63mm

30 = 0.75mm

31 = 0.80mm

35 = 0.90mm

40 = 1.00mm

50 = 1.27mm

63 = 1.60mm

70 = 1.80mm

73 = 1.85mm

75 = 1.91mm

87 = 2.21mm

91 = 2.31mm

93 = 2.36mm

95 = 2.41mm

99 = 2.54mm

Other Lengths Available

|

|

| |

| |

|

| |

| |

| WARNING - THIS PRODUCT CONTAINS LEAD |

|

Ingestion may cause lead poisoning. Do not breathe dust or fumes. Use NIOSH approved respiratory protection when necessary. Use only with adequate ventillation. Wash hands before eating, drinking, and smoking. Keep out of reach of children. For industrial and commercial use only. Do not re-use container. Not for use in potable water systems. See material safety data sheet for further information. |

| |

| California Regulatory Information |

| California State Proposition 65 |

| WARNING! This product contains lead, known to the state of California to cause cancer, birth defects and other reproductive harm. (California Health & Safety Code 25249.5 et seq.) |

Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models. Download Solidworks® e-Drawing viewer to enjoy 360° rotatable models.

| |

|

TopLine Corporation

95 Highway 22 W

Milledgeville, GA 31061, USA

Toll Free USA/Canada (800) 776-9888

International: 1-478-451-5000

Email: sales@topline.tv

©2024 TopLine. All Rights Reserved.

Home

|

|

|

|